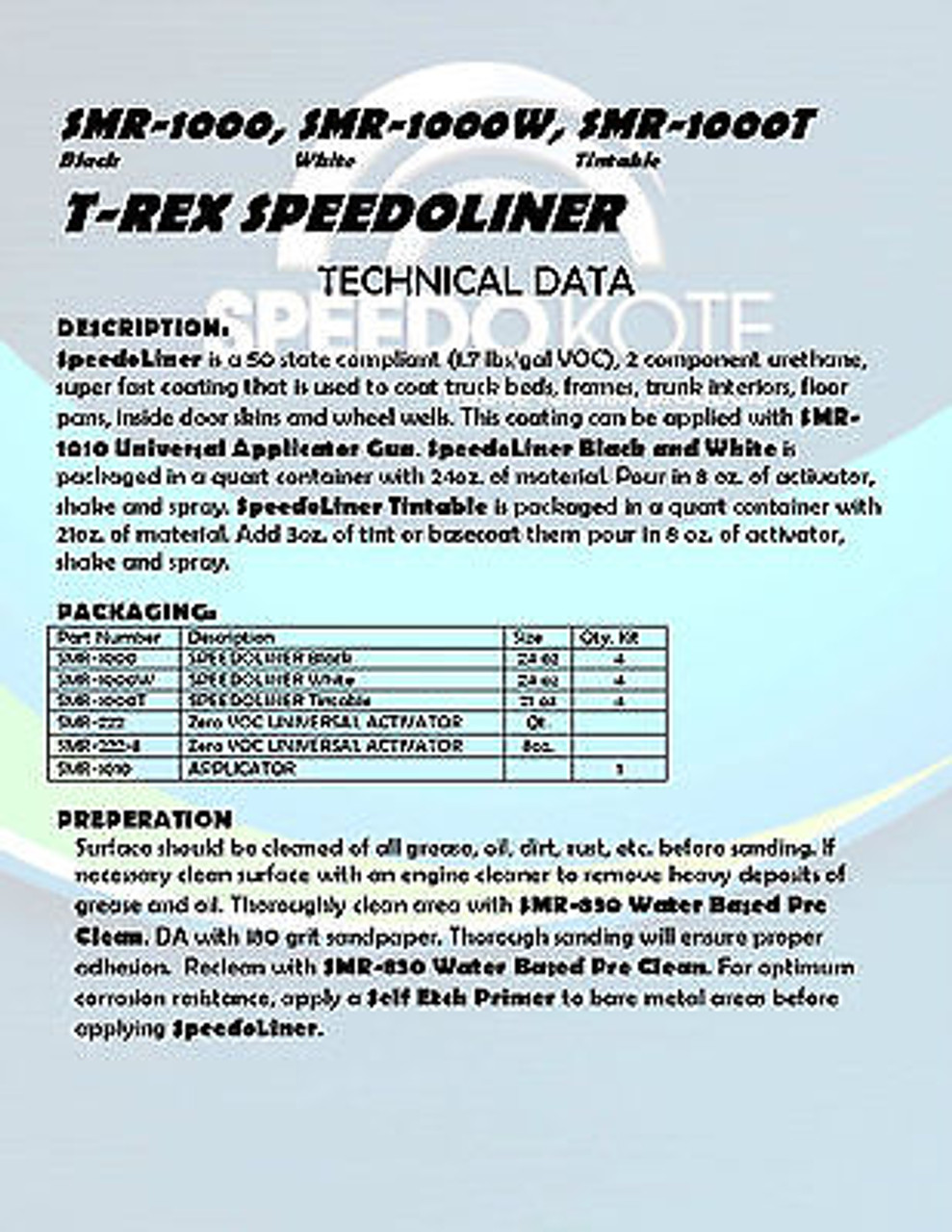

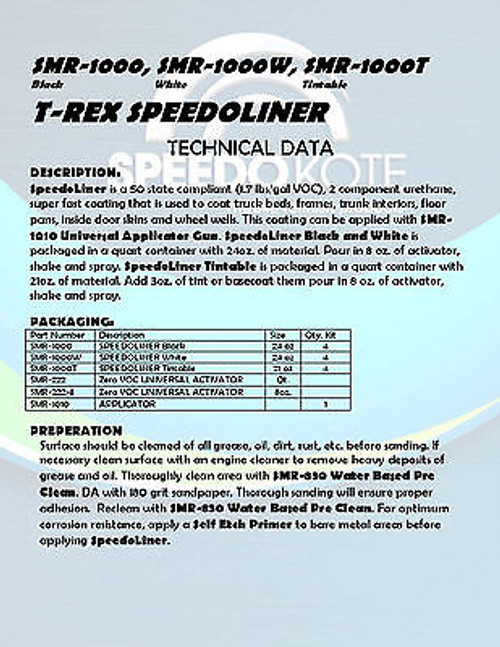

Product Description

4 plastic quart bottles of White Bed Liner (SMR-1000W) and a quart of SMR-222 activator; which when mixed yields one gallon sprayable. Also included is a mixing cup for measuring activator. NO SPRAY GUN.

Note: If one gallon of sprayable bedliner is not enough for your job, then you may add SMR-1000W-K1 from ebay.

The SMR-1000W is a 1.7 lbs/gallon voc and is the only bed liner that is 50 state compliant.

SMR-1000W is a true 2K urethane with outstanding adhesion to steel and sanded paint.

This coating is formulated to withstand the same atmospheric conditions as a high quality single stage urethane topcoat.

FEATURES:

.True 2K Urethane Durability

.Uniform White Color

.Excellent Exterior Stability from UV Light

.Fast Dry

.Chemical Resistant Finish

• Easy to use: ADD hardener - SHAKE - SPRAY (see instructions below)

• Abrasion and Stain Resistant

• Protects against rust, corrosion salt, damp & extreme temperatures

• Waterproof, flexible, helps deaden sound & vibrations

• Apply with shutz gun at different pressures to obtain different textures

• Provides excellent adhesion

SURFACE PREPARATION:

Surface should be cleaned of all grease, oil, dirt, rust, etc before sanding.

Wash area with soap and warm water, then rinse and dry.

Thoroughly clean area with Wax and Grease Remover.

Scuff surface with 180-220 grit sandpaper.

Re-clean with wax and grease remover, then dry with a clean towel.

Instructions: Apply Bed Liner between 60 - 85 degrees F and humidity less than 70%, Not in direct sunlight.

1. Add 8 ounces of SMR-222 activator to a quart bottle of SMR-1000W.

2. Screw on quart bottle cap and shake for two minutes.

3. Remove the cap and screw in the Shutz Spray Gun.

4. Adjusting the air pressure (60-80 PSI) and spray distance will change the texture.

5. Apply a uniform wet coat of bed liner using a sweeping motion.

6. After a 2 minute flash, apply a very light 2nd coat, sprayed at 80 PSI, using a fast sweeping motion.

Specification:

Usable Pot life at 70 degrees F / 20 degrees C : 60 minutes

Touch Dry at 70 degrees F / 20 degrees C : 1 hour subject to film build.

Light duty: 2 days at 70 degrees F / 20 degrees C.

Regular duty: 5 days at 70 degrees F / 20 degrees C.

Health and Safety:

See Material Safety Data Sheet and labels for additional safety information and handling instructions.

*

The contents of this package may have to be blended with other components before the product can be used. Before opening the packages, be sure you understand the warning messages on the labels and MSDS’s of all components, since

the mixture will have the hazards of all its parts.

* Improper handling and use, for example, poor spray technique, inadequate engineering controls and or lack of Personal Protective Equipment (PPE), may result in hazardous conditions or injury.

* Follow spray equipment manufacturer’s instructions to prevent personal injury or fire.

* Provide adequate ventilation for health and fire hazard control.

*

Follow company, product MSDS and respirator manufacturer’s recommendations for selection and proper use of respiratory protection. Be sure employees are adequately trained on the safe use of respirators per company and regulatory

requirements.

* Wear appropriate PPE such as eye and skin protection. In the event of injury, see first aid procedures on MSDS.

* Always observe all applicable precautions and follow good safety and hygiene practices.

Product Videos

Custom Field

Product Reviews

1 Review Hide Reviews Show Reviews

-

SMR-1000W-K4NG T-REX WHITE BED LINER

Been using this product for a few years now. It works great, easy to work with. Will keep buying it for sure.