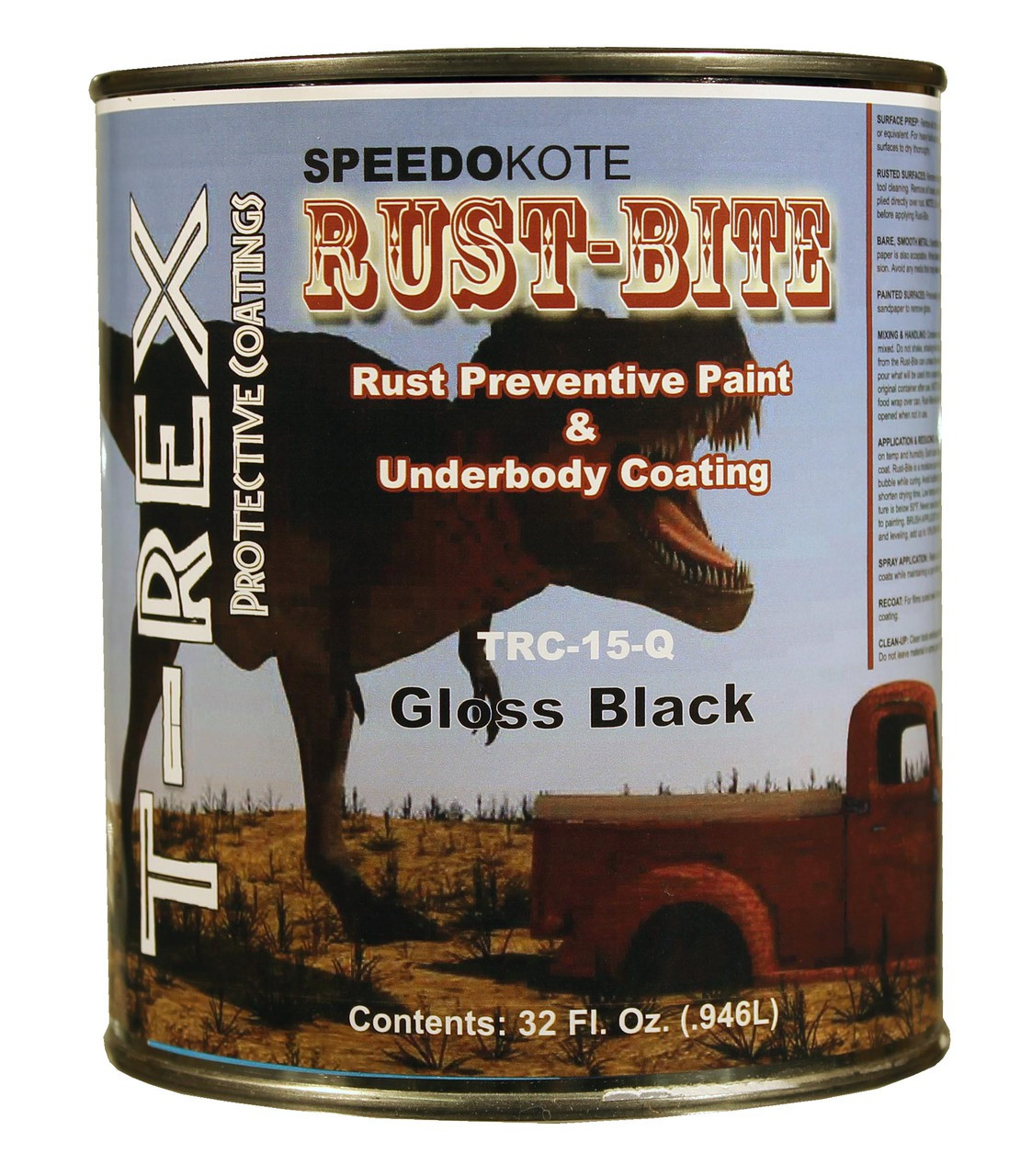

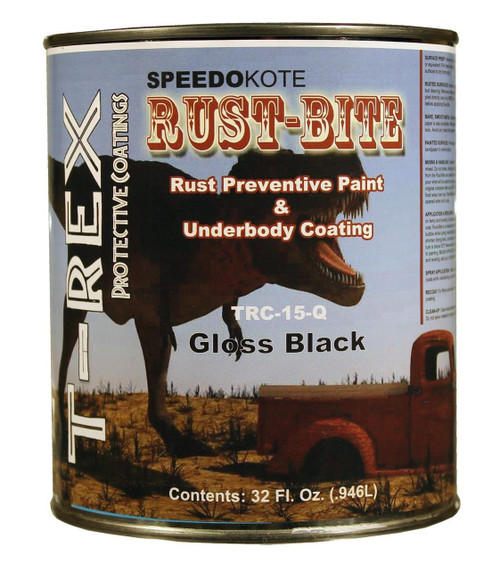

Product Description

TRC-15-Q, Rust Preventive Underbody Gloss Black Paint.

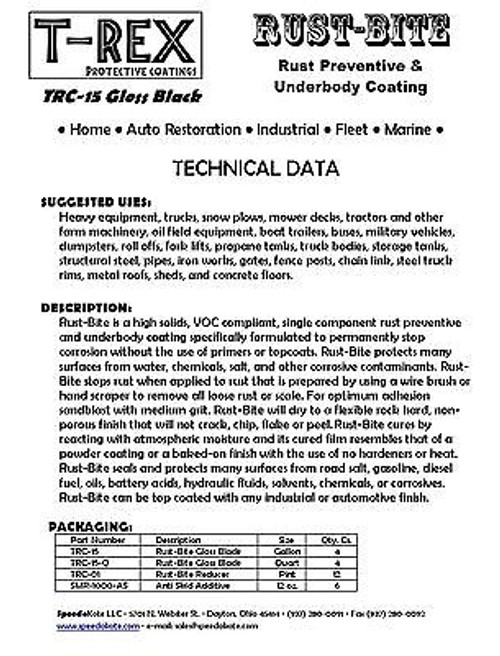

TRC-15 Gloss Black

• Home • Auto Restoration • Industrial • Fleet • Marine •

TECHNICAL DATA

SUGGESTED USES:

Heavy equipment, trucks, snow plows, mower decks, tractors and other

farm machinery, oil field equipment, boat trailers, buses, military vehicles,

dumpsters, roll offs, fork lifts, propane tanks, truck bodies, storage tanks,

structural steel, pipes, iron works, gates, fence posts, chain link, steel truck

rims, metal roofs, sheds, and concrete floors.

DESCRIPTION:

Rust-Bite is a high solids, VOC compliant, single component rust preventive

and underbody coating specifically formulated to permanently stop

corrosion without the use of primers or topcoats. Rust-Bite protects many

surfaces from water, chemicals, salt, and other corrosive contaminants. Rust-

Bite stops rust when applied to rust that is prepared by using a wire brush or

hand scraper to remove all loose rust or scale. For optimum adhesion

sandblast with medium grit. Rust-Bite will dry to a flexible rock hard, nonporous

finish that will not crack, chip, flake or peel. Rust-Bite cures by

reacting with atmospheric moisture and its cured film resembles that of a

powder coating or a baked-on finish with the use of no hardeners or heat.

Rust-Bite seals and protects many surfaces from road salt, gasoline, diesel

fuel, oils, battery acids, hydraulic fluids, solvents, chemicals, or corrosives.

Rust-Bite can be top coated with any industrial or automotive finish.

PREPARATION

Remove all dirt, grease or oils, clean surfaces using a Wax & Grease

Remover or equivalent. For heavy build-up scrape or wire brush excess

material prior to degreasing. Allow surfaces to dry thoroughly. NOTE: Do

not apply Rust-Bite if atmospheric temperature is below 50°F.

RUSTED SURFACES:

Remove loose rust and scale using a stiff wire brush, by grinding, or hand

tool cleaning. Remove all loose, peeling or bubbling paint. NOTE: Rust-Bite

works best when applied directly over rust. NOTE: Do not remove all rust or

apply any type of Rust Converter before applying Rust-Bite.

BARE, SMOOTH METAL:

Sandblasting is recommended but sanding with 36 to 80 grit sand-paper is

also acceptable. When blasting, provide a medium to coarse profile for

optimum adhesion. Avoid any media that may leave a smooth surface.

PAINTED SURFACES:

Previously painted surfaces should be sanded using a 120 to 180 grit

sandpaper to remove gloss.

MIXING & HANDLING:

Container may be under slight pressure. Stir liquid gently until uniformly

mixed. Do not shake, shaking will cause Rust-Bite to build pressure in can.

Never work directly from the Rust-Bite can unless the entire contents will be

used in a single painting session. Always pour what will be used into a

separate container.

NOTE: Never pour unused product back into original

container after use.

NOTE: Before closing Rust-Bite container apply a sheet

of plastic or food wrap over can, Rust-Bite will adhere lid to can if plastic is

not applied.

Never allow can to sit opened when not in use. WEAR

GLOVES DURING USE Skin contact should be avoided. Do not attempt to

remove dried Chassis Saver from skin with solvent; soak in warm, soapy

water. Once product has stained skin, only time will remove it.

APPLICATION & REDUCING:

Apply 2-4 coats allowing 3 to 8 hours between coats depending on temp

and humidity. Each coat should be dry to touch with no tackiness before

applying next coat. Rust-Bite is a moisture cure finish which when applied

too heavy will have a tendency to bubble while curing. Avoid bubbling by

applying thin coats only. Higher temps and humidity will shorten drying

time. Low temp and humidity will lengthen dry. Do not apply Rust-Bite if

temperature is below 50°F. Never use lacquer thinner as a reducer for Rust-

Bite or to wipe surfaces prior to painting.

BRUSH APPLICATION:

Apply thin, even coats using a nylon brush. For better flow and leveling, add

up to 10% TRC-01 Reducer.

SPRAY APPLICATION:

Reduce up to 10% using TRC-01 Reducer. Apply medium-wet coats while

maintaining a gun distance of 12 to 14 inches. Spray tip size should be: 1.2 to

1.4mm.

NOTE:

For surfaces that will be

exposed to UV (sunlight), apply a UV resistant single stage urethane paint after 3 - 24 hours.

RECOAT:

For films cured over 24 hours, sand using 400-grit abrasive to remove

gloss before recoating.

Health and Safety:

See Safety Data Sheet and labels for additional safety information and handling instructions.

* The contents of this package may have to be blended with other components before the product can be used. Before opening the packages, be sure you understand the warning messages on the labels and SDS’s of all components, since

the mixture will have the hazards of all its parts.

* Improper handling and use, for example, poor spray technique, inadequate engineering controls and or lack of Personal Protective Equipment (PPE), may result in hazardous conditions or injury.

* Follow spray equipment manufacturer’s instructions to prevent personal injury or fire.

* Provide adequate ventilation for health and fire hazard control.

* Follow company, product SDS and respirator manufacturer’s recommendations for selection and proper use of respiratory protection. Be sure employees are adequately trained on the safe use of respirators per company and regulatory

requirements.

* Wear appropriate PPE such as eye and skin protection. In the event of injury, see first aid procedures on SDS.

* Always observe all applicable precautions and follow good safety and hygiene practices.

Product Videos

Custom Field

Product Reviews

1 Review Hide Reviews Show Reviews

-

Rec-15q

Great product, goes on with ease, seals and covered completely in one coat, but followed directions and did two. Nice gloss finish, made the frame look better than new. Loads of help from sales and tech. All my vehicles and trailers will be coated for “ No Rusty Stuff”